| Home | My New Layout | Diagram of My Layout | My OLD Layout | LV & WR MRRC Scenery Work | C&O Berkshire & Live Trains |

CTC How-To Lesson |

CTC Wiring

(Centralized Traffic Control)

|

Understanding the system.

|

| You simply need to reverse the blue section while traveling over the black and green sections. (Once you clear the blue section, on the way into the loop, you can flip the direction switch for section A and it will be reversed and ready when the train heads back out of the loop.) Now, all we have to do is control how we keep + on the right and - on the left when we reverse directions on a section of track. This function is accomplished with one toggle switch for each section of the layout. It requires a simple DPDT toggle switch. DPDT = double pole - double throw (like two - 2 position switches combined). Click here to see an animation of the procedure. |

Diagram 4 |

The SPDT knife switch (diagram 4) can connect the center pole contact to the left, the right, or remain off (in between). |

A SPDT switch. |

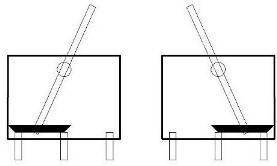

This is a side view of a typical SPDT switch (cut-away view). Notice that the CENTER & LEFT contacts close when the lever (protruding from the top of the switch) is pushed to the RIGHT. Likewise, the CENTER & RIGHT contacts close when the lever is pushed to the LEFT. The center contact is called the COMMON contact - the contact common to both positions. You can learn more about switch (& circuit) basics here and here. |

A miniature DPDT switch. |

A DPDT switch is like 'gluing' two SPDT switches side-to-side to make one unit which works on a single lever. Likewise, a 3PDT (3 pole - double throw) switch is like three SPDT switches 'ganged together'. To change the engine direction, you have to control the wires to both sides of the track plus you need an OFF position too: DPDT On-Off-On switches. It is also critical that it can handle the current pull expected so use at least 2 amp (2A) switches. (DPDT On-Off-On switches with 2A contact ratings.) I suggest about 4A - 5A switches for long, dependable life. |

|

Now you're ready to start wiring the switches to perform 'magic' and give you real control of your trains. Click here to go to the next page and learn about CTC direction wiring. |